testing in production the hard parts|production problems in testing : exporters Depending on your definition of testing, there’s a long list of activities and techniques related to software quality that can be considered “testing in production.” What follows is a non-exhaustive list of some of such activities: 1. Chaos Engineering 2. . See more Consulte a previsão do tempo e clima para a agricultura e boletins especiais para Marau. Sol com muitas nuvens. Pancadas de chuva à tarde e à noite. Média probabilid. Sol com muitas nuvens durante o dia. Períodos de nublado, com chuva a qualquer hora. Sol com algumas nuvens. Chove rápido durante o dia e à noite. Sol e aumento de nuvens .

{plog:ftitle_list}

Cremonese: ecco tutte le news e ultim'ora di oggi. Segui su g.

Before you go any further in the article, it’s essential we’re on the same page in regard to what “testing in production” means. That’s why we’re going to start by defining the term. So, what is testing in production? Well, let’s start by clearing up a common misconception. Testing in production does notmean . See moreWe’ve started the post by saying that testing in production, when done right, can net you unique benefits. Now it’s time to talk about said benefits. Why should you do production testing? See moreDepending on your definition of testing, there’s a long list of activities and techniques related to software quality that can be considered “testing in production.” What follows is a non-exhaustive list of some of such activities: 1. Chaos Engineering 2. . See moreEverything changes amazingly fast when it comes to the software industry. Sometimes what seemed unthinkable a few years ago becomes commonplace and that’s exactly what . See more

What is Testing in Production? Why Test on Production when you can test on Staging? How to test in production? Best Practices for Testing in Production Testing in production helps you learn and experiment with how users react to a specific feature or code. For example, when releasing new features, QA engineers perform testing in production to check whether the .

Production testing metrics are invaluable tools in the software development process. They provide quantitative data and insights into the quality, efficiency, and performance of testing in production. Testing in production enables the QA team to introduce new code changes, test them, and make them live instantly. Hence, it becomes easier for the Engineering teams to respond to user requests quickly and release .

instrumentation laboratory analyzer distributors washington

Testing in production helps you learn and experiment with how users react to a specific feature or code. For example, when releasing new features, QA engineers perform testing in production to check whether the .

Testing in production refers to the practice of conducting automated tests after an application has been deployed to production. Production tests help ensure that quality does not get left behind as new, untested . Introduction. Every software must be tested in three environments – Test, Staging, and Production. Testing in Production (TIP), rather, refers to the continuous testing of the application in the production environment after a . Testing in production allows you to conduct an in-depth product review in a real-world setting, and it is the only method to confirm that the system performs as expected. .

Each final assembly (top level, or Product) is tested and inspected before being shipped. The amount of testing and inspection varies with the product requirements, but a typical product .

After that, we’ll cover testing in production in a bad way; Finally, we’ll show how to test in production in the correct way; Hopefully, by the end of the post, you’ll understand the reasons why testing in production is an .Use the automated testing tool: Once the manual cycle of integration testing is complete, the best practice is to start automating the test cases to reduce manual effort and time. Prioritization: Prioritize test cases based on criticality and risk. Test data management: Prepare the test data close to production data to ensure real-world simulation.Testing during design vs manufacturing. During design, the main focus of your testing strategy will likely be to exercise the design across multiple dimensions (e.g., power supply voltage, temperature, vibration, load) to validate that the .

Production Testing as the Future – Many organizations are concerned about the notion of testing extending into production since testing has often certified the quality of the software before delivery to production. However, testing is evolving drastically as a result of agile and DevOps, and organizations must pick the best approach to adapt. . 7075 Aluminum. It is as strong in the tensile as some mild steels. It is also amazingly rigid for aluminum. In fact, I often use 7075 shafts for testing in place of steel shafts.The Brinell hardness test involves indenting a material with a hard sphere under a specific load. Two diameters (x and y axis) of the indentation are measured, and the hardness value is determined based on the load applied. Brinell belongs to the optical methods. Brinell Hardness The Vickers hardness test utilizes a pyramidal diamond in-

Here are the key challenges that are encountered in Testing in production and need to be addressed. Security Risks: As we test live and real data in testing in production, testers must ensure the security of crucial data by preventing data leakage. Breaking Production: A test in a production environment will either pass or fail. And the test .

Testing in production is a software testing approach that involves conducting various testing activities directly in the live production environment. Unlike traditional testing, which usually occurs in staging or pre-production environments, Testing in production evaluates an application’s behavior and performance under real-world conditions . That is to say, in-production testing is meant to supplement rather than replace testing in a pre-production environment. . You won’t be able to test every single user interaction situation before the product is released, no matter how hard you try. Developers can monitor app performance in real-world scenarios by testing in production.

Plastic materials that are frequently tested for hardness include plastic sheeting and molded parts. Products such as rigid thermo-plastics, Plexiglas, thermo-polystyrene, vinyl sheeting, cellulose acetate, and thermosetting laminates such as Formica are commonly tested for hardness too.Obsolescent Parts & FPGA Emulation; Rad-hard environment operations; . This source is used for qualification testing of electronic components per MIL-STD 883, TM 1019, which requires testing to be performed in the dose rate range of 50-300 rad(SiO2)/s. . characterization and production testing of custom ASIC devices and commercial off-the .

Now production testing is an integral part of any large system. We’ll explore some of the concepts used in production testing and show how Functionize can help you do this intelligently. . Tamas Cser, at UCAAT (the leading industry conference). The system consists of three main parts, user journey tracking, prediction, and anomaly detection .Hardware QA testing continues throughout production and is typically less involved than pre-production testing; rather it functions as a product verification of the hardware as it is produced. Testing during mass production has a very different purpose: to ensure that the 10th and 50,000th product coming off the assembly line are the same .

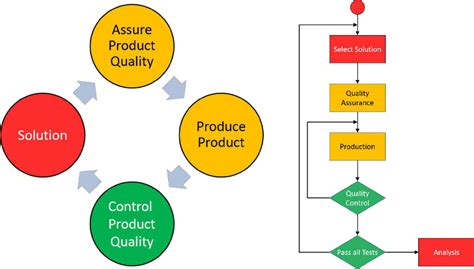

testing in production process

For more information on unittest, you can explore the unittest Documentation.. nose. You may find that over time, as you write hundreds or even thousands of tests for your application, it becomes increasingly hard to understand and use the output from unittest.. nose is compatible with any tests written using the unittest framework and can be used as a drop-in replacement for the . The Navy seeks to maximize its use of AM to fabricate "hard to source" or obsolete parts, reduce cost, field more effective systems, and reduce reliance on vulnerable supply chains through production at the point of need. . The solution should be able to test parts that fit within a 20" Wide x 12" Deep x 12" High volume. The system itself . Failure To Test Sample Parts Inexperienced Supplier Inferior Leak Testing Method Poorly Designed Equipment Ineffective Customer Training . High production rate Hard vacuum helium leak test. Sample parts are tested. Resolve part contamination issues Test high speed test concepts Designed and built multi-chamber, robotic loaded system. .What is Unit Testing? Essentially, a unit test is a method that instantiates a small portion of our application and verifies its behavior independently from other parts.A typical unit test contains 3 phases: First, it initializes a small piece of .

instrumentation laboratory analyzer distributors west virginia

To verify mass production yields with one production-worthy design (one configuration for each shipping SKU) To qualify the first hard tool for every part in the assembly TYPICAL QUANTITIES: 300 to 2000 All parts should be from hard tools or mass production capable processes All functional test stations must be present with limits in place to

Peculiarities of additive technologies are considered, and the most typical flaws are listed. The possibility of layer-by-layer nondestructive testing of parts immediately in the course of additive manufacturing is demonstrated. Based on the review of domestic and international publications, possibilities that are offered by various physical methods of .Learn how to prepare powder metallurgy parts for metallographic analysis with accurate and reproducible results. . Rockwell is a fast hardness test method developed for production control, with a direct readout, mainly used for metallic materials. The Rockwell hardness (HR) is calculated by measuring the depth of an indent after an indenter .Depending on what's being measured or tested, engineers can make changes on the spot. In other cases, test findings may require an extensive rethinking of how a part or set of parts function. To make sure the entire testing process stays reasonably on schedule, manufacturers make multiple "test mules," or pre-production cars, for testing.

testing in production pdf

Testing in production allows you to perform an in-depth product review in a live production environment, and it is the only way to ensure that the system works as intended. Read on to learn more about testing in production and why it is critical to the development process. What is Testing in Production. In a nutshell, Testing in production (TiP .

Production testing is most powerful than a few types of testing in particular: Stress testing is a way of establishing how the application handles heavy loads. These tests can be in the form of a spike test, where large amounts of traffic are suddenly sent through and designed to illuminate points at which the application needs to be scaled.

quantities. Through the TEMP, DOT&E can approve the use of production-representative test articles in lieu of production test articles. In evaluating whether systems are production-representative, DOT&E will consider whether the test articles were assembled using the parts, tools, and manufacturing processes intended for use in full-rate . Material versatility: Hard tooling can be designed to work with a variety of materials, making it adaptable to different production needs. Disadvantages of Hard Tooling. High initial costs: The creation of hard tools can be expensive, which can be a barrier for small businesses with limited budgets.Electrical Safety Test – this is typically a Ground Bond and Hi-Potential test to be sure any structural parts are properly grounded, and any electrical conductors are properly insulated. Stress Screening – some products are operated for a time at elevated temperatures to stress components and weed out any marginal components or weak .

Testing in production is valuable because it eliminates a category of problems that occur because of environmental drift between your production and testing environments. Rather than testing in a dedicated environment and then deploying code that passes to your production environment in the hopes that its behavior remains consistent, you .

testing in production examples

web18 de jun. de 2020 · 2.3M views 3 years ago. Follow the Subway Surfers on the World Tour to historic Zurich!!-. Expand your surfer crew with Hugo, the curious inventor- Unlock Hugo’s new Pirate .

testing in production the hard parts|production problems in testing